Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

A riveting machine is a mechanical device used to perform riveting operations. Riveting is a method of permanently joining two or more workpieces together by forming rivets or studs on the workpieces. The riveting machine forms and presses the rivets or studs onto the workpieces by applying pressure, thus forming a secure connection. This method of joining is commonly used to join metal workpieces, providing a reliable mechanical connection without the use of welding or bolts.

A riveting machine is a mechanical device used to perform riveting operations. Riveting is a method of permanently joining two or more workpieces together by forming rivets or studs on the workpieces. The riveting machine forms and presses the rivets or studs onto the workpieces by applying pressure, thus forming a secure connection. This method of joining is commonly used to join metal workpieces, providing a reliable mechanical connection without the use of welding or bolts.

Key Features:

◆ Powerful pressure system: Riveting machines are usually equipped with powerful hydraulic or pneumatic systems that can provide enough force to form a strong riveted connection;

◆ Punch (die) design: The punch is a tool used to apply pressure and form rivets or rivet studs. Its design depends on the type of riveting required and the characteristics of the workpiece, and it is usually replaceable to adapt to different workpieces;

◆ Versatility: Some riveting machines have a multifunctional design that can adapt to workpieces of different shapes and sizes, as well as perform different types of riveting operations, such as blind riveting, squeeze riveting, etc.;

◆ Accurate control system: Modern riveting machines are usually equipped with advanced control systems, which ensure the accuracy and repeatability of operations through programming or automated control;

◆ Safety system: Riveting machines are usually equipped with safety systems, including emergency stop buttons, protective covers, etc., to ensure the safety of operators and equipment;

◆ Workbench and positioning system: The workbench of the riveting machine is used to support and position the workpiece, and usually has an adjustable function to accommodate workpieces of different sizes and shapes;

◆ Sturdy machine tool structure: In order to maintain stability under high pressure and high load, the machine tool structure of the riveting machine is usually designed to be sturdy;

◆ Multi-material applicability: Riveting machines are usually suitable for a variety of materials, including metals and plastics, to meet the needs of different industrial fields;

◆ High degree of automation: Some riveting machines have automation functions and can be integrated into the production line to achieve a highly automated production process;

◆ Easy to maintain: The design focuses on easy maintainability, facilitating daily maintenance and repair to ensure the stability and reliability of the equipment;

Product parameters:

| Product Model | YY6-500C | YY8-500C | YY10-500C | QY5-500C | QY8-500C |

| Drive Mode | Fully hydraulic | Pneumatic (3-6bar) | |||

| Output pressure range | 0.5-6T | 0.5-8T | 0.5-10T | 0.5-5T | 0.5-8T |

| Throat depth | 500mm | ||||

| Safety protection | Random standard | Standard | |||

| Hard limit | / | ||||

| Motor power | 2.2KW | 3.75KW | 5KW | / | |

| Equipment weight | 490KG | 520KG | 560KG | 480KG | 500KG |

| Pressure repeatability | ±1% | ||||

| Holding time | 1~5s | ||||

| Pressing rate | 65mm/s | 100mm/s | |||

| Throat height | 380mm | 365mm | |||

| Laser light assisted positioning | Optional | Optional/Standard | |||

| Voltage | 220V | ||||

| External network size | 1070mm×650mm×1695mm | 1070mm×650mm×2095mm | |||

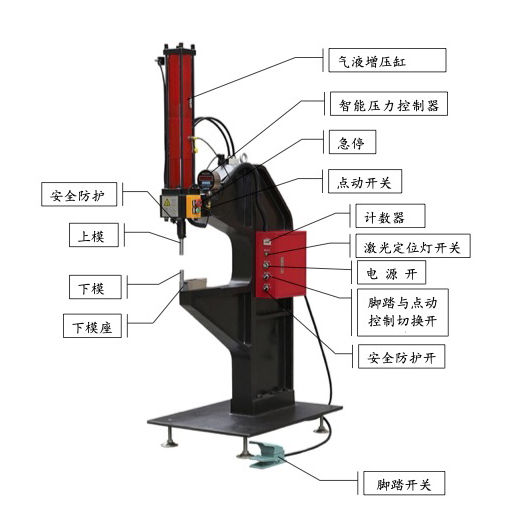

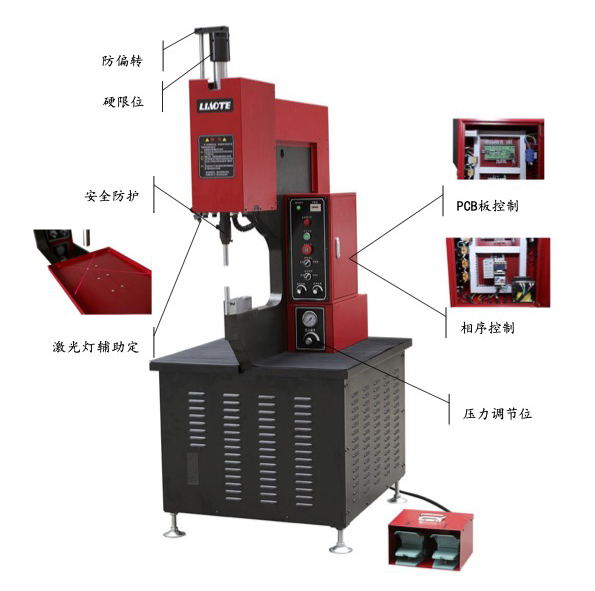

Product structure:

The operation process of the riveting machine usually includes the following steps:

Press riveting machines are widely used in the manufacturing industry, especially in automotive manufacturing, aerospace, electronics and other industries that require high-strength connections. Different types of press riveting machines are used for different sizes and types of riveting tasks.

评价

目前还没有评价