Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

This machine has a wide range of uses and is suitable for recording movements, cameras, clocks, radio components, hardware, steel and wood furniture, shutters and all areas that require riveting. It is a popular hardware machine in developed countries.

The precision automatic riveting machine produced by our factory is a new type of riveting equipment put into production and use in the mainland based on decades of production experience in Japan and Taiwan; This machine adopts the working principle of electrical integration to complete the riveting action of rivets. The spindle runs smoothly, riveting has no impact, no noise, precise positioning, simple and firm appearance, low center of gravity, strong rigidity, beautiful form, and the spindle can be adjusted in two stages, which expands the riveting range; The failure rate is low and almost no maintenance is required; The special forming principle makes the riveted parts very firmly connected, which is much stronger than the pressure riveting connection. There is no need to worry about the riveting parts loosening after long-term use, which extends the service life of the product and improves the quality of the product; One-time riveting forming is much more efficient than bolt connection, and the cost of rivets is much lower than that of bolts, which is very helpful to reduce product costs. The riveted surface is smooth and flat, and the plating will not be damaged during riveting. It is the preferred equipment to improve the quality of metal riveted surfaces and product quality and reduce product costs.

This machine is fully functional. According to the different designs of the rivet rod, it can rivet countersunk, semi-circular, cylindrical, spherical cylindrical rivets and hollow rivets. It can also use the rotating extrusion of the rivet rod to squeeze the concave countersunk platform to make the platform surface bright. The advanced circuit design can realize the automatic action of riveting, ensure the consistency of the riveting time each time, and improve the qualified rate of products. When using automatic operation, the timer can be adjusted to the most suitable time at will, which greatly improves the production efficiency and controls the output of the shift, reducing human loss.

This machine has a wide range of uses and is suitable for recording movements, cameras, clocks, radio components, hardware, steel and wood furniture, shutters and all areas that require riveting. It is a popular hardware machine in developed countries.

Key Features:

1. Low noise: Due to the use of rotary pneumatic transmission and the installation of a muffler, there is no noise pollution; the lubricating oil mixture is discharged from the rear of the machine, so there is no harm to the human body.

2. Simple operation: just step on the foot switch to start riveting automatically.

3. Short riveting time: For example, it only takes 0.3 seconds to process a ψ3mm rivet.

4. Good processing quality: Due to the use of special mechanism, the riveting surface is smooth and accurate, and the riveted rivets will not be roughened or deformed.

5. Wide range of applications: Different rivet head types can be riveted by changing the rivet rod (as shown in Figure 1).

Technical parameters:

| Model | HD -132 | HD -136 | HD- 141 | HD- 141A | HD -143 | HD -143A | HD- 150 | HD- 152 | HD- 155 | |

| Motor (Oil Pump Motor) | 1/4HP | 1/4HP | 1/2HP | 1/2HP | 1HP | 1HP | 1 × 2HP | 1 × 2HP | 2 × 3HP | |

| Spindle travel | 25mm | 35mm | 40mm | 40mm | 40mm | 40mm | 40mm | 40mm | 40mm | |

| Rivet Capacity (Mild Steel) | solid | 0.3 — 3 | 0.5 — 4 | 1 — 7 | 1 — 7 | 2 — 9 | 0.5 — 5 | 3 — 12 | 3 — 12 | 3 — 25 |

| Hollow | 1 — 6 | 1 — 8 | 1 — 15 | 1 — 15 | 1 — 20 | 1 — 9 | 3 — 25 | 3 — 25 | 3 — 40 | |

| Time adjustment (seconds) | 0.5 — 10 | 0.5 — 10 | 0.5 — 10 | 0.5 — 10 | 0.5 — 10 | 0.5 — 10 | 0.5 — 10 | 0.5 — 10 | 0.5 — 10 | |

| Use pressure | 1 — 6 | 1 — 7 | 2 — 7 | 2 — 7 | 3 — 7 | 3 — 7 | 20 — 70 | 20 — 70 | 20 — 100 | |

| Maximum pressure | 100-480 | 70-700 | 230-800 | 230-800 | 460- 1100 | 460- 1100 | 430-1650 | 430-1650 | 1400-5500 | |

| Mechanical height (adjustable) | 680 | 790-890 | 940- 1050 | 1050-1170 | 1150-1220 | 1050-1220 | 1750 | 1600 | 2000 | |

| Rivet length (maximum) | 100 | 100 | 150 | 280 | 200 | 150 | 180 | 230 | 300 | |

| Throat depth | 90 | 105 | 120 | 120 | 125 | 125 | 170 | 160 | 200 | |

| Rivet head speed | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | |

| Maximum working surface | 150 × 250 | 180 × 250 | 190 × 320 | 190 × 320 | 190 × 320 | 190 × 320 | 190 × 320 | 140 × 240 | 160 × 260 | |

| Weight (kg) | 50 | 80 | 120 | 128 | 170 | 180 | 300 | 350 | 450 | |

| Dual axis distance (adjustable) | 35- 150 | |||||||||

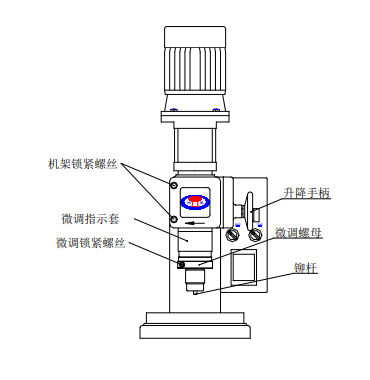

Product structure:

Reviews

There are no reviews yet.